Using Fenetex’s Bond Pro App, you can control your retractable screens, pergola roofs, lights, fans, and more without having to use a proprietary remote control for each device.

Check it Out

Insect Screens in Action

Your patio is a sanctuary; enjoy it on your own terms. Fenetex Motorized Insect Screens are there when you need them, gone when you don’t. Deploy them at the touch of a button to relax and enjoy your deck without bothersome bugs. New construction or retrofit, we’re there for you.

The Fenetex Difference

Insect Screen Advantages

Built to Last

Our insect screens utilize a welded end retention system, ensuring longevity and durability against winds up to 100 mph. Fenetex insect screens are built with the same engineering and craftsmanship as our heavy-duty hurricane screens. This method of construction outperforms all other types of screens in this industry.

Total Control

Push a button and control your environment, raising or lowering your screens with ease; or use smart home integration to get your screens just where you want them when you need them. We offer a variety of control options to suit your needs.

Self Adjusting

Fenetex Motorized Insect Screens use our Quiet Spring technology which means they are self-adjusting to keep your screens smooth and wrinkle-free. Aesthetics matter, we know.

Dual Protection

Pair our retractable insect screens with other Fenetex screens for customized and independent solutions. Each screen operates independently, giving you the protection you want when you need it.

Total Control

Our insect protection solution, ideal for doors and bug screens, is motorized for easy deployment at the touch of a button. For ultimate peace of mind, pair with smart home automation systems for remote operation and monitoring, even deploying automatically in emergencies.

We’ve successfully integrated our insect screens with all the major home automation brands. At first, we were pioneers, then we became experts.

Our beautiful handheld remote works with our Fenetex Smart Motors and can control up to 15 insect screens independently or an unlimited number of screens within 15 zones.

We stock three brands of motors that are used depending on the customer's needs and the application. All motors are specified when ordering screens though our online ordering portal.

The world’s first quiet self-adjusting screen system

Fenetex introduced the patented quiet spring technology, the core of our One-Track system, nearly a decade ago.

We’ve crafted the perfect self-adjusting screen system that operates beautifully and silently when deployed, ensures frustration-free operation, and can be used in almost any weather condition.

While others have experimented with alternative methods to achieve the advantages of our One-Track screens, none have achieved the unique combination of near-silence, ease of operation, affordability, high reliability, and exceptional dependability.

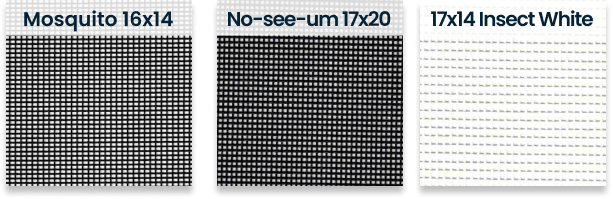

Material Options

We offer two different densities of insect screens depending on what bugs you want to keep out – a tighter weave to stop small insects like no-see-ums and a slightly more open weave to block mosquitoes.

Our Welding Process

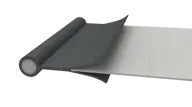

Fenetex keder is an assembly where a PVC cord is overwrapped by a low-friction PVC-coated fabric that can be attached to a screen edge.

One

Perfecting Keder Performance over a Decade

We've engineered our keder with specific cord hardness, fabric densities, and PVC coatings. Our formula for this has been perfected over a decade of manufacturing and real-world use to ensure the best possible performance.

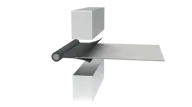

Two

A High-Energy Joining Process

A precisely cut screen edge is inserted into a Fenetex keder. Welding bars located above and below the screen will come together when the welding cycle is initiated.

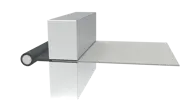

Three

The Molecular Level Fusion of Keder and Screen

When the welding cycle is initiated, the bars clamp down on the materials with a precise amount of pressure. Then, 10kW of RF energy is briefly pulsed through the material. This creates a lot of heat, welding the materials together. Finally, a cooling phase under pressure sets the weld.

Four

Backed by a Lifetime Warranty

Once the weld cycle is complete, the keder and the screen are now permanently joined at the molecular level and cannot be separated. There are no zippers to break, no adhesives to fail, and no stitching to wear out. Our process is so reliable that our screens are backed by a lifetime warranty.

Resources

Technical Library

All of our products are inspected according to both our own meticulous in-house processes as well as a nationally recognized third-party quality assurance program, ensuring that everything that leaves our warehouse out-performs the competition.